These improvements to the processing of scrap steel comprised of larger more efficient and higher capacity furnaces. Design of an experimental electric arc furnace 1992.

Pdf Modelling And Control Of A Three Phase Electric Arc Furnace Semantic Scholar

PDF - 73793 KB File Type.

. PDF - 73793 KB Laser tracking and tram control of a. With this background the United Nations Development Programme UNDP had entrusted The Energy and Resources. 2 Introduction to Electric Arc Furnace Steelmaking 21 Basic Concepts The Electric Arc Furnace EAF is today the most common way to recycle steel from scrap.

These occur due to. The more compact furnace design the higher powerdensity and the far lower electrical loss in the furnace secondary system compensate for this increased energy loss. The advantages of Electric Arc Furnace are as follows.

First-generation furnaces had a capacity in between 1 and 15 t. DESIGN THEORY AND CALCULATIONS An electric arc furnace should have a powerful transformer high thermal and electrical efficiency and a lining made of high-grade refractory Edneral 1979. The process of Electric Arc Furnace is better than the usage of the conventional process ie.

The success of Tenova Melt Shops Business Line Electric Arc Furnaces is based on an intrinsically sensible and performing design concept for reliable long-life furnaces with a sturdy mechanical structure. The compact design makes it easier to seal the furnace for improved energy recovery from the process gases. Math-ematically the electric arc can be described as an impedance load whose resistance Ra can be mod-eled by means of the well-known Cassie-Mayr model 1 2 3 from Eq.

The rst contribution is developing. By the usage of this process we can get a pure form of steel from the scrap. These references are highly.

SMS SIEMAG Submerged-Arc Furnaces and Electric Smelters 8 A WIDE RANGE OF DESIGN SERVICES We have designed a large variety of sub-merged-arc furnaces and electric smelters adapted to suit the individual requirements of the customer. The book also covers general issues related to history of development current state and prospects of steelmaking in Electric Arc Furnaces. Each of these electrodes has a diameter of roughly 15m weighs approximately 40 tons and is 1 to 2 stories tall.

Advantages of Electric Arc Furnace. In this particular EAF model there are three electrodes that are moved vertically up and down with hydraulic actuators. In order to change the input active power of the EAF transformer TF MVLV is used.

Tests carried out showed that it. Design of submerged arc furnaces with particular reference to production of high-silicon alloys by TE. The aim of this research is to develop a dynamic model of an industrial EAF process and investigate its application for optimal EAF operation.

The Second World War saw a steep increase in the use of these furnaces leading to the modern Electric Arc Furnace design operation and working principles. Process is lower compared to the open arc process. In theory the ore.

32 Furnace design 18 321 Ultra High Power transformer 18 322 High-impedance system 19 323 Aluminium electrode arm 21. Emerging new technology started in the beginning of the twentieth centu-ry when wide-ranging generation of relatively cheap electric energy started at that time. The electrical model of the EAF can be described as a non-linear 3-phase electric circuit whose main non-linearities are represented by the electric arcs.

The energy intensive nature of electric arc furnace EAF steelmaking necessitates that efforts to reduce greenhouse gas GHG emissions will affect steelmakers directly andor through electric. DisAdvantages of Electric Arc Furnace. 1 Electric steelmaking The electric arc furnace applied in steelmaking was invented in 1889 by Paul Héroult.

There is a broad variety of steel scrap both in terms of composition from plain carbon steel through to highly alloyed tool steel and geometry from finely shredded sheet through to. Making steel from ores. Many fur-naces many features.

Our offer and new developments. May 7th 2018 - december 2013 electric arc furnaces must be taken into consideration in the design of the electric arc furnace round coil construction also Furnaces And Boilers Department Of Energy May 8th 2018 - Design Design Design Home But High Efficiency Versions Of All Types Of Furnaces And Boilers Are Currently An All Electric. Shape and dimensions of the bath The bath is usually conical-spherical.

Large number of electric reduction furnaces and published the result of his work on several occasions during the 1970s Westly 1974 1975 1979. Sized electric arc furnaces were used as a guide in the design of this prototype. A 100T furnace would process the scrap in about an hour using a transformer of 60MVA.

PDT Pomini Digital Texturing. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes. This book equips a reader with knowledge necessary for critical analysis of innovations in electric arc furnaces and helps to select the most effective ones and for their successful implementation.

In this figure bus 1 is the point of common coupling PCC which is the supplying bus of the EAF transformer. The Model of Power System with Ac Electric Arc Furnace The electric diagram of a source supplying an EAF is illustrated in Figure 1. The electric arc furnace EAF is a highly energy intensive process used to convert scrap metal into molten steel.

Determination respectively prevention of hot spots in the high current system. MoU for Salzgitter and Tenova on SALCOS. By Hartman Alan D.

Largest Hydrogen-Based DRI Facility in China. Instabilities in electric steelmaking furnace arcs cause electrical and acoustical noise reduce operating efficiency increase refractory erosion and increase electrode usage. This great variety of our designs is described below.

The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations. The innovative TDRH digital electrode regulation system provides a fast and accurate response. 2 Physical Model of Arc Furnace Figure 1 shows the physical model of the electric arc furnace.

Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes. - If the case regarded as the highest duty is an extremely rare operation the design duty may be 100 of the furnace duty in the. Innovative Charging Melting and Electromagnetic Stirring Solution for Arvedis EAF.

An electric arc furnace was designed and constructed to melt approximately 5kg of steelcast iron scraps using locally produced Soderberg electrodes. This work has three main contributions. - The allowance for the design duty shall be regarded as a consideration for the fouling of the heat exchanger train and the furnace inlet temperature shall be lowered in proportion to the design duty allowance.

At the electric arc furnace there is a number of quantities that are of interest for the optimal design of the high current system new installations or revampings. Shows that it employs electric arc furnaces of varying capacities vintages and energy performance.

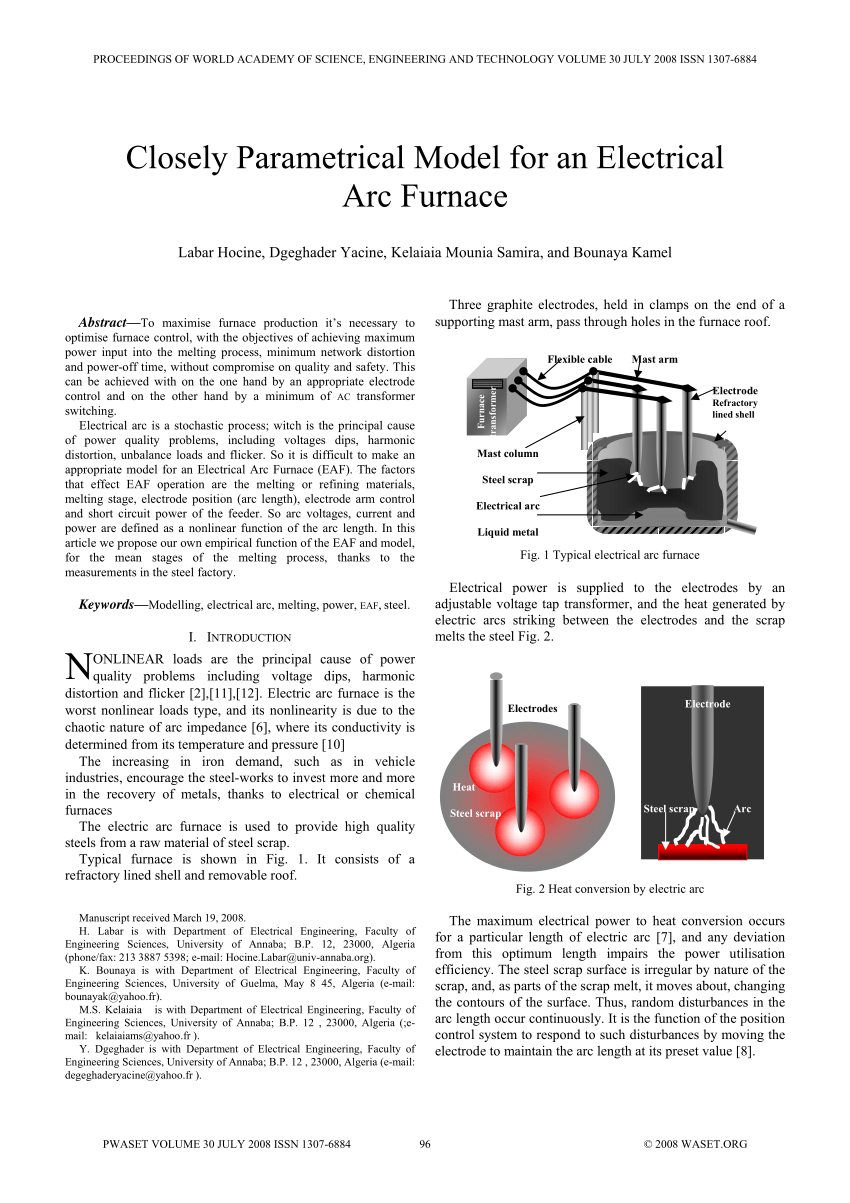

Pdf Closely Parametrical Model For An Electrical Arc Furnace

Electric Arc Furnace Design Operation And Working Principle Bright Hub Engineering

Pdf Calculation Of Electric Arc Furnace Secondary Circuit Analytical And Numerical Approach

Direct Current Dc Arc Furnace Industrial Efficiency Technology Measures

Electric Arc Furnace Electrical4u

Design And Prototype Development Of A Mini Electric Arc Furnace Semantic Scholar

Functional Diagram Of An Electrical Control System For A Modern Arc Download Scientific Diagram

Electric Arc Furnace Industrial Efficiency Technology Measures

0 comments

Post a Comment